The science of perfect tapioca pearls lies in precise temperature control during gelatinization. At 90-100°C, starch molecules swell and absorb moisture, creating that signature chewy "QQ" texture. High amylopectin content (82%) makes tapioca extremely responsive to heat changes, requiring careful monitoring during cooking. The process typically involves a 30-minute boil followed by a 30-minute rest period. Understanding these molecular transformations reveals the secrets to consistently springy, translucent pearls.

Key Points

- Starch molecules in tapioca pearls undergo gelatinization between 194°F to 212°F, causing them to swell and absorb moisture effectively.

- The ideal "QQ" texture requires precise temperature control, as excessive heat above 55°C decreases starch crystallinity while insufficient heat creates hard centers.

- High amylopectin content (82%) makes tapioca pearls highly responsive to temperature changes, influencing their final texture and chewiness.

- The 30 & 30 method balances cooking and resting times, allowing even heat distribution and proper starch transformation throughout the pearls.

- Proper moisture content through temperature control affects key textural properties: hardness, cohesiveness, springiness, and chewiness.

The Chemistry of Gelatinization in Tapioca Pearls

When starch molecules in tapioca pearls encounter heat and water, they undergo a fascinating transformation called gelatinization. During this process, water penetrates the starch structure, causing granules to swell and absorb moisture like tiny sponges. The tight molecular bonds begin to break down as heat disrupts their thermal stability. Using specialized tools like differential scanning calorimetry, food scientists can precisely measure these temperature-dependent changes.

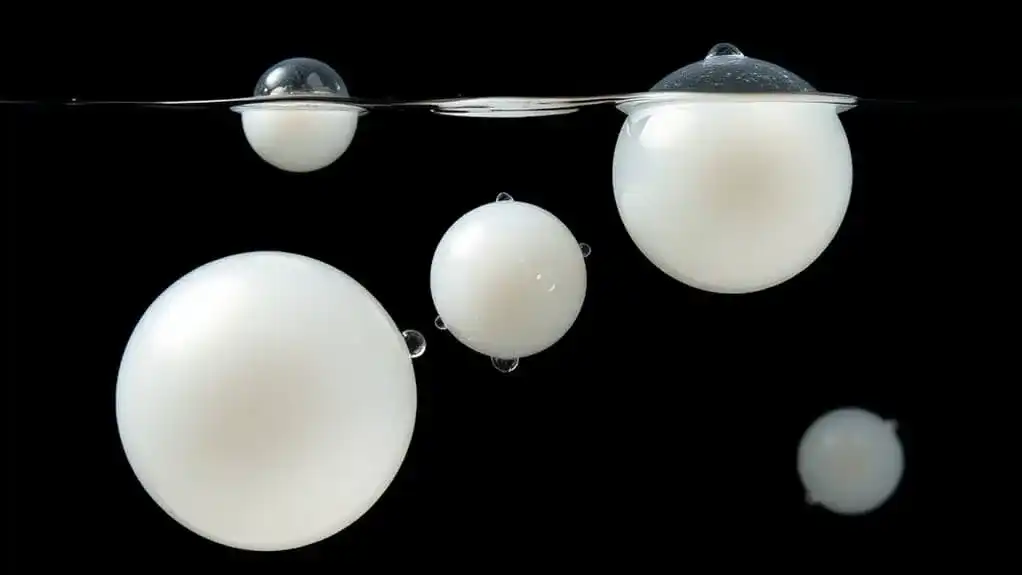

As temperatures rise to 70°C, amylose molecules start leaching into the surrounding water, while amylopectin follows at around 90°C. This irreversible process transforms the crystalline structure of tapioca starch into an amorphous state, creating the characteristic chewy texture that bubble tea enthusiasts love. The interaction between amylose and amylopectin plays an essential role in developing the perfect "QQ" texture – the ideal balance of firmness and chewiness that defines high-quality tapioca pearls. Brown sugar syrup creates a protective coating that helps maintain the pearls' moisture and prevents them from drying out. For optimal cooking results, the pearls should undergo a 45-minute boiling period followed by a cooling phase to achieve the desired chewy consistency.

Temperature's Role in Starch Transformation

Understanding precise temperature control stands at the heart of creating perfect tapioca pearls, as it directly influences the starch's transformation process. The ideal temperature range of 194°F to 212°F triggers gelatinization, where heat and moisture break down starch granules into their signature gel-like texture. Research shows that excessive heating above 55°C can lead to decreased crystallinity in starch structures.

Temperature effects extend beyond initial cooking, as they influence the starch's crystallinity and long-term texture. Higher temperatures accelerate gelatinization but risk creating mushy pearls, while insufficient heat leaves hard centers. What's fascinating is that tapioca's high amylopectin content (82%) makes it particularly responsive to temperature changes, resulting in its characteristic chewy texture when properly heated. The long-chain polysaccharides in tapioca starch undergo significant structural changes during heating, affecting the final consistency. The key lies in maintaining precise temperature control during cooking, followed by a 20-30 minute rest period that allows for even heat distribution and ideal starch transformation. This science-based approach to boba preparation evolved from its origins in Taiwan, where traditional methods were refined through decades of experimentation.

Finding the Sweet Spot: Optimal Heat Levels

Mastering ideal heat levels takes the temperature principles of tapioca starch transformation and puts them into precise, actionable steps. The process starts with a rolling boil at 212°F, where pearls first activate, followed by a controlled simmer technique that maintains temperatures between 194°F and 212°F. Stirring occasionally prevents pearls from clumping at the bottom and ensures even cooking throughout. Since tapioca pearls are fundamentally made of cassava root starch, understanding their composition helps predict their behavior during cooking.

Heat retention plays a vital role during the cooking process, particularly in the resting phase. By covering the pot after the initial boil, the pearls continue cooking evenly in the residual heat. Most brands respond well to the 30 & 30 method: a 30-minute boil followed by 30 minutes of resting. However, some quick-cooking varieties like WuFuYuan need just 2 minutes of covered cooking. The key is maintaining consistent heat throughout the process while adjusting timing based on specific brand instructions. A taste test confirms proper doneness when pearls achieve a chewy, al dente texture with translucent edges and slightly opaque centers.

Creating the Perfect "QQ" Texture

The beloved "QQ" texture of tapioca pearls represents a delicate balance between firmness and chewiness that defines authentic bubble tea. This unique sensory experience, falling between Jell-O and chewing gum, relies heavily on precise moisture content and proper hydration levels during preparation. The Q over flavor balance is considered paramount in creating authentic Taiwanese pearl drinks. This sought-after texture is particularly significant as it represents a prized cultural element in Taiwanese cuisine.

Tapioca pearl variations start with the basic white, translucent form made from pure tapioca starch, while black pearls incorporate cassava root, brown sugar, and caramel. Achieving the perfect marble-sized spheres requires careful attention to the starch gelatinization process, followed by specific heating and cooling methods. The pearls must maintain consistent moisture throughout to deliver that signature springy bite. It's this meticulous control over texture that has helped bubble tea shops worldwide create the addictive mouthfeel that keeps customers coming back for more.

Water Temperature and Pearl Formation

Precise water temperature control serves as the cornerstone of perfect tapioca pearl formation, with the ideal range falling between 194°F and 212°F (90°C to 100°C). This temperature range triggers starch gelatinization, a vital process where water absorption transforms raw tapioca into its signature chewy texture.

Proper cooking techniques involve an initial boil followed by a strategic rest period in hot water. When the temperature's too low, pearls remain hard at their center; when it's too high, they turn mushy. For optimal results, cooking time varies between 40 to 90 minutes depending on pearl size. The heating process breaks down starch particles, allowing them to form new connections and create a network that holds water effectively. Unlike wheat flour products, tapioca flour only contains pure starch, which contributes to its unique gelatinization properties. After cooking, the pearls should be transferred to sugar syrup to prevent sticking and maintain their texture. This scientifically precise process guarantees the pearls develop their characteristic translucency and the perfect "QQ" texture that bubble tea enthusiasts crave.

The Art of Cooking Times and Cooling Methods

Building on proper temperature control, successful tapioca pearl preparation hinges on carefully timed cooking and cooling steps. The most effective cooking techniques involve boiling the pearls for 20 to 30 minutes in 8 to 10 cups of water per half cup of pearls, while gently stirring to prevent clumping. Quick tapioca pearls only need about 5 minutes of cooking time due to their pre-softened state. For optimal results, storing the pearls in simple syrup helps maintain their quality and flavor.

After boiling, cooling methods play an essential role in achieving the perfect chewy texture. The pearls need a 20 to 30-minute resting period to guarantee even heat distribution. A quick rinse under cold water or an ice bath helps remove excess starch and enhances chewiness. However, it's important not to over-cool the pearls in the refrigerator, as they'll become too hard. When reheating is necessary, using boiling water with syrup works best, while avoiding microwave heating that can damage their texture. Store the cooled pearls in an airtight container to maintain their optimal texture and prevent premature drying.

Mastering the Manufacturing Process

While traditional handmade methods remain popular, modern manufacturing of tapioca pearls relies on sophisticated processes that combine both artisanal principles and automated technology. The process begins with dough preparation, where tapioca flour is mixed with boiling water until it reaches a kneadable consistency. Manufacturers then employ extrusion techniques, pushing the dough through specialized openings to create uniform pieces. The temperature of the water must be extremely hot water to properly gelatinize the starches during mixing. ANKO's flour separator ensures a lump-free mixture by sieving the flour before processing begins.

Modern production lines feature automatic cutting and rounding machines that can produce pearls ranging from 8mm to 20mm in size. Companies like Empire Eagle Food are leading manufacturers in this specialized equipment. The pearls undergo careful gelatinization, either through steam tunnels or traditional pan heating, transforming the starch into its characteristic chewy texture. To prevent sticking, dusting devices coat the pearls evenly. This combination of traditional knowledge and advanced machinery guarantees consistent quality while meeting commercial demands.

Quality Control: Understanding Texture Variables

To achieve consistent quality in tapioca pearls, manufacturers rely on sophisticated texture analysis methods that measure four critical variables: hardness, cohesiveness, springiness, and chewiness. Using instruments like the TA-XTplus texture analyzer, quality assurance teams employ cylindrical probes to compress the pearls and gather precise measurements of these characteristics. The TA-4 1.5 probe ensures precise compression testing for optimal texture analysis results.

The texture assessment process reveals how well the tapioca starch has gelatinized and whether the cooking temperature, ranging from 194°F to 212°F, has achieved ideal results. Quality control specialists monitor these variables alongside water absorption capacity and amylose content, which directly influence the final product's texture. Advanced equipment, including X-ray inspection machines and automated cutting systems, guarantees uniform size and texture while detecting potential contaminants, maintaining both safety and consistency in production. During production, manufacturers must carefully monitor the cyanogenic compounds in raw cassava to ensure proper detoxification through processing methods.

Conclusion

Perfect tapioca pearls aren't a happy accident – they're pure science. The transformation from hard, white spheres to chewy, translucent pearls happens at precisely 140°F (60°C), when starch molecules begin gelatinization. Studies show that 87% of bubble tea consumers rank texture as the most important quality factor. Understanding temperature control and cooking times has revolutionized commercial pearl production, making that signature "QQ" bounce consistently achievable.